Tools

Parts

No parts specified.

-

-

MINI-extruder-front

-

MINI-extruder-rear

-

MINI-extruder-idler

-

MINI-inspection-door

-

-

-

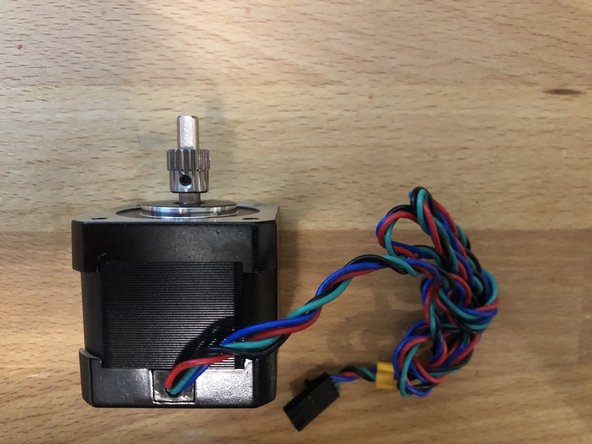

Extrude stepper motor

-

3 x 625z bearings

-

Extruder gear set

-

Spring

-

Idler pin

-

-

-

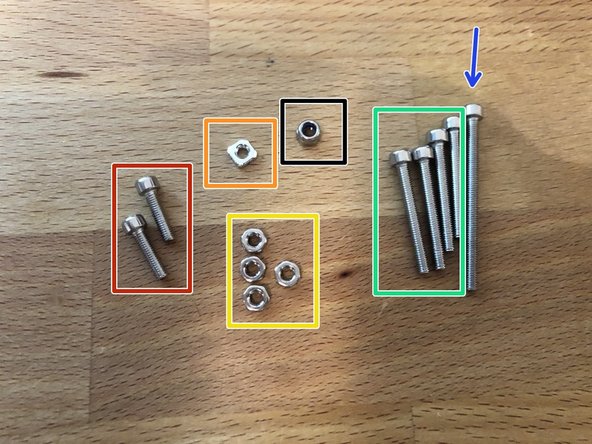

2 x M3 12mm

-

4 x M3 25mm

-

1 x M3 40mm

-

4 x M3n nut

-

1 x M3nS nut

-

1 x M3n Nyloc

-

-

-

Insert 3 x M3n nuts into the extruder back.

-

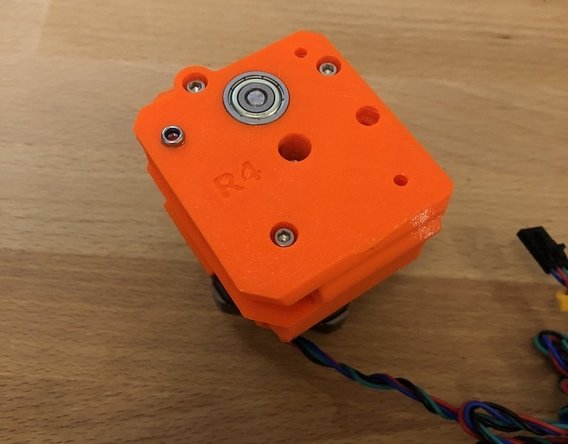

Insert 625z bearing into other side of extruder back (second picture).

-

-

-

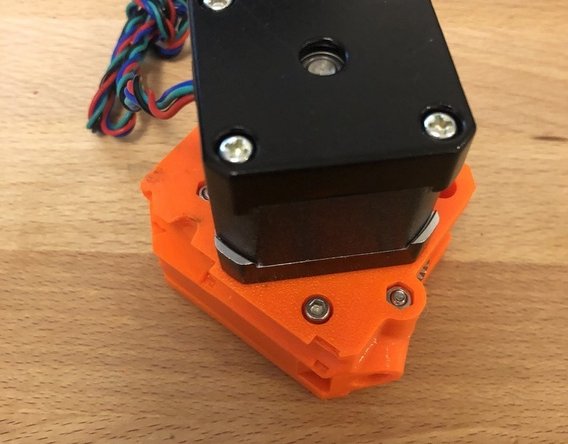

Add the small gear to the extruder.

-

Make sure the grub screw lines up with the flat on the shaft.

-

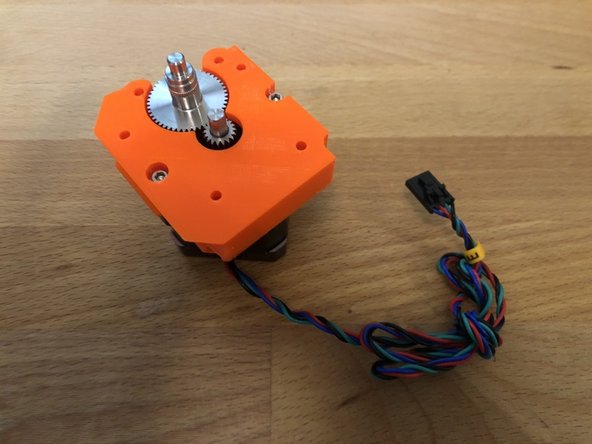

Using 2 x M3 12mm screws, attach the stepper to the extruder-front.

-

-

-

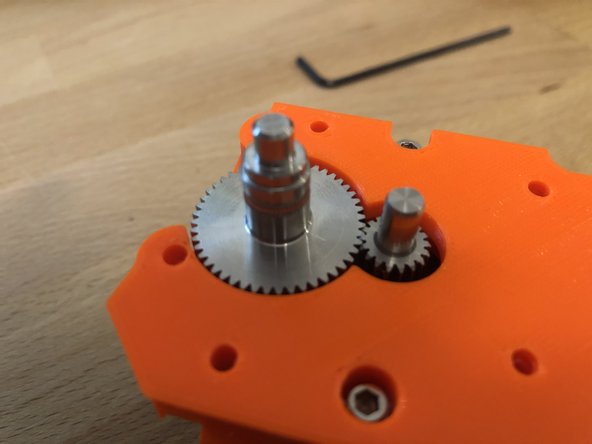

Add the reduction gear to the bearing as shown.

-

The reduction gear the the small gear should line up (pic 3)! If they don't (pic 2) then remove the stepper and move the small gear.

-

-

-

Insert M3sN nut into side of extruder idler.

-

Insert 625z bearing into top of extruder idler.

-

Insert bearing ping into side of extruder idler.

-

-

-

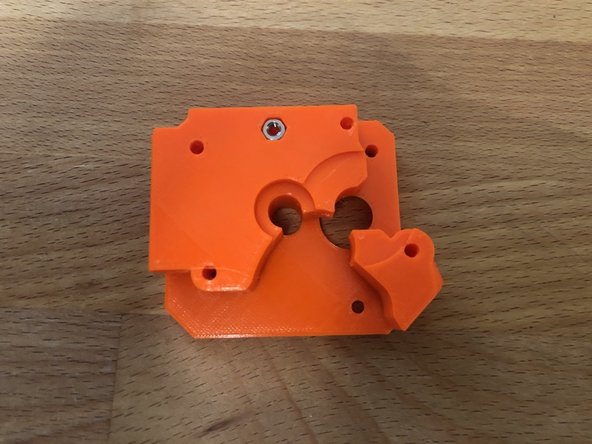

Add M3s nut to inside of the extruder rear.

-

Flip over the extruder read.

-

Be careful to ensure the nut doesn't fall out.

-

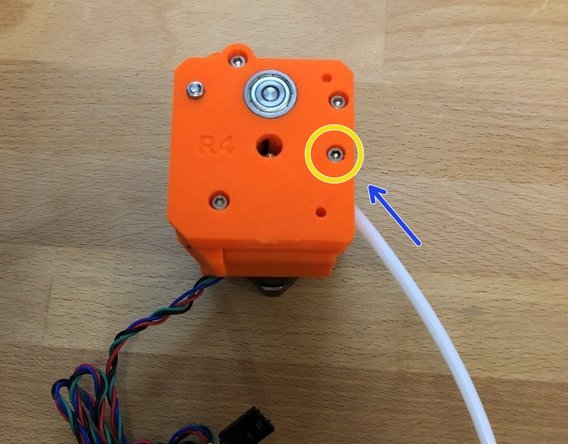

Insert M3s nyloc nut into top-left hole.

-

Insert 625z bearing into large middle hole.

-

-

-

Using 3 x M3 25mm screws, join the front and the rear of the extruder.

-

-

-

Add the extruder idler arm to the side of the extruder.

-

Flip the extruder over.

-

Using 1 x M3 25mm, secure the idler arm into the nyloc nut.

-

-

-

Insert the M3 x 40mm screw and spring into the bottom side of the extruder and tighten.

-

-

-

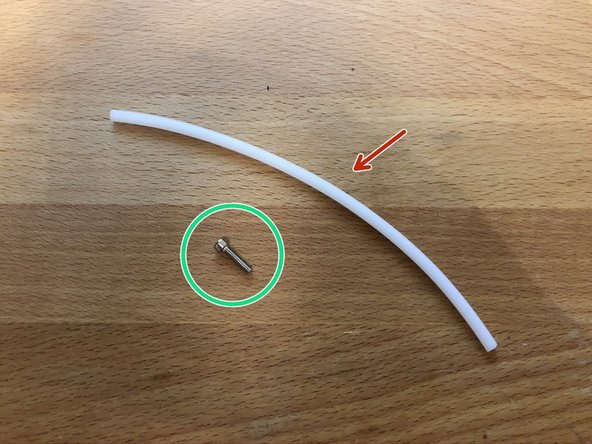

Gather 155mm teflon tube

-

Gather 1 x M3 12mm

-

Insert teflon tube into extrude input.

-

Secure with M3 12mm screw.

-